IFTLE has actually invested considerable time going over the absence of U.S.-based substrate manufacturing.

Although plans such as the ball-grid variety (BGA) were created by U.S. firms like Motorola, manufacturing ability was all off-shored to Asia years back. Having experienced U.S. manufacturing ability has actually constantly belonged to the United States reshoring program.

In IFTLE 513 we took a look at the IPC record “The IPC NA Advanced Packaging Ecosystem Gap Assessment” which is still a wonderful source for understanding this circumstance https://www.3dincites.com/2024/02/iftle-583-dod-funding-for- u-s-based-substrate-manufacturing/

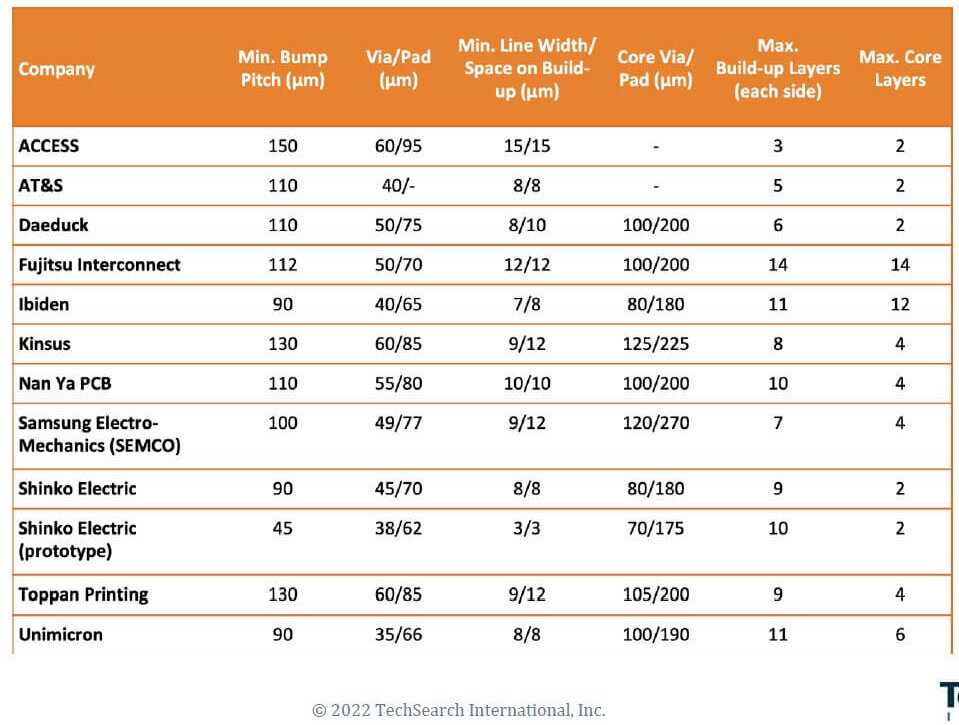

A peek at the globe’s significant substrate distributors validates that none have U.S.-based manufacturing (Number 1).

The Industrial Base Evaluation and Sustainment Reshore Ecological Community for Secure Heterogeneous Advanced Product Packaging Electronic Devices (IBAS IMPROVE) program, which laid out the innovative product packaging modern technologies that we required to implemented, had high-density accumulation (HDBU) substratums called out front and facility.

Nonetheless, the IBAS improve program did not need to money HDBU substrate manufacturing when it ended up being clear that Division of Protection (DoD) resources (particularly the Protection Manufacturing Act Financial Investment (DPAI) Program (Title III) would certainly be utilized for suchfunding That has actually lastly occurred over the previous couple of months.

Calumet Electronic Devices Corp.

In Nov 2023, the DoD revealed an honor of $39.9 million by means of the DPAI Title III program to Calumet Electronic devices Firm to “…enhance capabilities to produce High-Density Build-Up (HDBU) substrates, which include High-Density Interconnect Printed Circuit Board (PrCB) cores and HDBU build-up layers.”

Dr. Laura Taylor-Kale, Aide Assistant of Protection for Industrial Base Plan mentioned “These technologies are critical for modern weapons systems and will contribute to maintaining our warfighting edge over potential adversaries.”

The honor will supposedly make it possible for Calumet to scale up design, tooling, and manufacturing procedures to develop residential manufacturing capacities for HDBU substratums. HDBU substratums and innovative product packaging are crucial allowing modern technologies for sixth-generation systems and applications, consisting of for radar, digital war, handling, and interactions.

Calumet likewise obtained $7.5 million in motivations from the Michigan Economic Advancement Firm by means of the Michigan Strategic Fund to sustain the firm’s arising capacity to make it possible for next-generation DoD modern technology in crucial multifunction applications. The state offered added tax obligation and residential property motivations in its plan.

The brand-new 60,000-square-foot manufacturing center, beside its existing procedures, will certainly be the initial of its kind in the USA, according to the Michigan Economic Advancement Firm. The center will certainly consist of Course 1000 Tidy areas to broaden natural substrate manufacturing for the country, specifically as it connects to interaction and digital war.

Calumet, situated in the top peninsula of Michigan, was included in 1968 and supposedly, materials ~ 4MM conventional PCB/yr.

GreenSource Manufacture

The Division of Protection revealed an honor of $46.2 million to GreenSource Manufacture

The honor will certainly boost existing manufacturing capacities at a manufacturing center of cutting edge incorporated circuits (IC) substrate, high-density adjoin (HDI) and ultra-high-density adjoin (UHDI), and progressed product packaging.

Dr. Taylor-Kale kept in mind that “Expanding domestic production capability for printed circuit boards and advanced packaging is necessary to avert a shortfall that would severely impair national defense capability.”

The honor will certainly make it possible for GreenSource to scale up design, tooling, and manufacturing procedures to develop a specialized center for IC substrate manufacture for a high-mix, low-volume offering of innovative adjoin services. These residential manufacturing capacities for HDI, UHDI, IC substratums, and progressed product packaging are crucial allowing modern technologies for sixth-generation systems and applications, consisting of radar, digital war, data processing, and interactions.

In both these instances it would certainly not be reasonable to anticipate cutting edge (SOTA) capacity to be produced instantly. One need to totally anticipate 2-3 years of installment and credentials to really create procedures that would certainly be taken into consideration SOTA with today’s international manufacturing (see table over). Best of good luck to Calumet and GreenSource, yet to be honest, IFTLE would certainly have been much more comfy if, additionally, we had actually obtained among the significant gamers noted in the above table to develop ability in the United States.

For all the current in innovative product packaging remain connected to IFTLE … ……

#shorts #hungry #birds #girls #beautifulgirls #prank

#shorts #hungry #birds #girls #beautifulgirls #prank