Likewise: United States CHIPS Looking For < < $300M Propositions

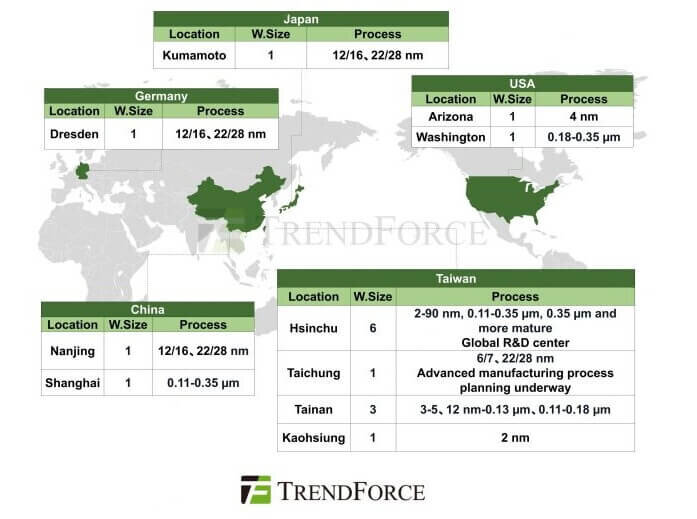

TSMC’s Offshore Fabs

Nikkei Asia is reporting that TSMC’s $8B Japan chip task steams in advance as its united state website remains to strike grabs. TSMC has actually released considerable international development in the united state, Japan, and Germany to resolve expanding consumer need and expand manufacturing impacts. TSMC Chairman Liu states the firm required to globalize to maintain and broaden its innovation and production management.

The ability of TSMC’s offshore fabs being developed abroad represent much less than 10% of its complete capital expense. TSMC’s most current Worldwide Manufacturing ability as explained by Trendforce is received Number 1.

TSMC’s offshore fabs consist of the Arizona fab, the fab it is integrating in Kumamoto, Japan, and the fab it is mosting likely to construct in Germany. They are all various in area, configuration, and extent.

Device installment at TSMC’s Japan Kumamoto plant began in October 2023 with manufacturing to start in 2024. TSMC has actually started setting up devices at its brand-new chip plant in Japan showing that the task is continuing extra swiftly than the firm’s sophisticated center in the united state. The $8 billion plant gets on track to fulfill its target of starting manufacturing by the end of following year and might also lead routine. The Kumamoto task was revealed in October 2021, building started in 2022 and automation is anticipated in 2024. The Kumamoto plant will certainly begin making use of 28-nm and 22-nm manufacturing innovation, which is reasonably fully grown and can create chips such as picture sensing units, driver-integrated circuits, and microcontrollers that are utilized in every little thing from smart devices to vehicles.

TSMC has actually supposedly sent out thousands of assistance team to the website in Japan, to be signed up with by hundreds extra from TSMC distributors. TSMC has actually informed a number of distributors that the installment of chip manufacturing devices will certainly be finished in the initial quarter of 2024.

The chipmaker has actually additionally sent out a number of hundred “seed” workers experienced in running such plants to Japan given that the summertime, along with employing in your area to get ready for plant configuration. Providers sent off one more couple of hundred designers to aid establish the center in October. The Japanese federal government has supposedly structured policies that allow TSMC to raise its supply chain and job quicker. TSMC showed that “the Japanese industry has a very strong ecosystem in materials, gas, substrates, and wafers. Having access to that is very strategic.”

The reasonably smooth progression at TSMC’s initial chipmaking center in Japan stands in raw comparison to its plant in Arizona, in the United States, which will ultimately generate 4-nm chips. Prepare for the Arizona center began in mid-2020, building started the list below year, and manufacturing, which was initially slated to start in 2024, has actually been pressed back to 2025.

“In each site, we work closely with our customers, partners, and vendors to understand cost, labor, and regulatory factors and move forward accordingly.”

Records suggest that Japan has far better chip sector facilities than the united state and has actually been even more punctual with federal government assistance. Japan has actually currently allocated $3.5 B well worth of aids for the TSMC task. The united state just settled the CHIPS Act, a plan of assistance for the sector, in the last couple of months and has yet to designate its funds. On top of that, the United States CHIPS Act limits receivers from broadening chip production in “countries of concern” for ten years.

united state policies are extra challenging, he stated, making it challenging for TSMC to bring its greater than 100 distributors to collaborate with it in Arizona. The slower allotment of American aids might additionally boost the moment it takes chipmakers to set up devices in brand-new plants.

Others have actually kept in mind the functioning society in Japan and Taiwan as an aspect behind the Kumamoto task’s progression, in addition to less logistics difficulties. Records suggest that “Culturally, Japanese and Taiwanese workers are more accepting of long, grueling work hours and monthly schedules that most American workers will find hard to live with.”

Chairman Mark Liu recognized that TSMC has actually needed to experience a “learning curve” throughout this abroad development.

An essential Japanese devices distributor that knows with TSMC’s development in Taiwan, Japan, and the united state states that “… In Taiwan, it’s possible to hoist semiconductor equipment in just one day with a crane, while in Japan, it might take two or three days. In the U.S., it might take more than a week. This affects the speed of building the factory.”

There is additionally the trouble of locating sufficient certified employees in all 3 areas, according to Capri of the Hinrich Structure. “Engineers, physicists, computer scientists, and other skilled positions are in short supply for the chip sector.”

CHIPS for America Small-Scale Provider Task Financing

CHIPS for America has actually revealed that it is approving small distributor task idea strategy entries in the application site (2023-NIST-CHIPS-SMME-01).

CHIPS for America has actually revealed that it is approving small distributor task idea strategy entries in the application site (2023-NIST-CHIPS-SMME-01).

This financing chance looks for applications for tasks for the building, development, or innovation of industrial centers for semiconductor products and making devices with capital expense of much less than $300 million.

The application procedure consists of 2 main stages. In the initial stage, candidates will certainly be asked to send a principle strategy explaining exactly how their recommended task addresses core program top priorities. Idea strategies will certainly be approved in between December 1, 2023, and February 1, 2024. The Division will certainly after that welcome one of the most appealing candidates to the 2nd stage.

The Division is specifically curious about applications that progress collections by shutting important voids in the united state distributor landscape. If a task does not sustain a collection, the application should make an engaging instance for progressing among the Division’s various other 2 goals. will certainly have the chance to send a complete application.

The Idea Strategy ought to go to many 2 web pages. Candidates ought to offer an in-depth summary of the task and the candidate. Please note, a lot of this details will certainly additionally be gathered in the internet site. The listed here lays out the standard needs:

Task Summary

Explain the building, development, or innovation tasks recommended.

Explain what will certainly be created and their end market applications.

Explain the range, dimension, and ability of manufacturing.

Candidate Summary.

Candidate account.

For all the most recent in Advanced Product packaging task satay connected to IFTLE … … …