As the power thickness boosts for semiconductor tools, thermal management is ending up being an ever before much more vital difficulty for dependability and efficiency, for high-performance computer, AI, information facility, power electronic devices, and various other applications. Warmth dissipation is usually a fantastic worry as the joint temperature level increases with an enhanced power thickness, which can negatively impact the efficiency and dependability of the semiconductor tool. This is a lot more complicated and tough for heterogenous assimilation, with several chips of numerous performances, dimensions, and power circulations, and the consequent thermal efficiency demands– done in the exact same bundle.

For this function, numerous thermal management solutions have actually been under development in the sector and academic community. Unique thermal user interface products (TIM), such as stage adjustment products (PCM), fluid steel alloys, graphene, graphite, and composite products, have actually been established for high thermal conductivity and reduced thermal resistance. Cooling down solutions, consisting of warmth spreaders, warmth sinks, and warmth pipelines– in numerous alloys and arrangements, along with vapor chambers, jet impingement, microchannels, and straight fluid air conditioning (or immersive air conditioning), have actually likewise been subjects of extensive development job worldwide.

In such development job, it is usually preferable to be able to quickly define the efficiency of the brand-new remedy, to ensure that renovations can be made promptly. In case of TIM, for instance, simply having the small thermal conductivity information is not adequate, as the efficiency of the TIM in genuine applications is usually influenced by the real usage atmosphere, especially the user interfaces with the various other elements in the stack-up. Various other sensations, such as nullifying and pump-out throughout power biking, can likewise dramatically impact the efficiency of the TIM.

In this initiative, an usual difficulty has actually been the demand for an unbiased examination automobile that can assist properly and successfully define and assess the efficiency of the numerous thermal management solutions, to ensure that enhancement and optimization models can be implemented quickly, maximized solutions can be established and reviewed, and sensible evaluation can be made for numerous applications.

The choice of utilizing a genuine practical chip for this function is usually not functional, for numerous factors. Initially, development job for thermal management solutions requires to happen simultaneously with the development of a brand-new chip, i.e., prior to the brand-new chip appears, to speed up the moment to market for the brand-new tool. Second, having the whole practical chips powered on and completely functional takes a large amount of initiative, usually past the capacities of business (such as a products vendor) whose emphasis is to create the thermal management remedy, not the chip itself. Third, genuine practical chips are really pricey and usually not also readily available to distributors of thermal management solutions. Ultimately, as there are many various chips that call for the thermal management remedy, it is not functional and affordable for the vendor of thermal management solutions to utilize many various contribute the training course of creating and maximizing the thermal management remedy (such as a TIM).

Why We Required Thermal Management Examination Cars

Reliable examination automobiles are required to allow the rapid development of thermal management solutions. Such devices and capacities can assist speed up the development job and lower the price of creating thermal management solutions. The examination automobile requires to be able to very closely replicate the real semiconductor chip, in terms of the product, dimension, and non-uniform power circulation of the chip, along with the real application atmosphere, such that the real setup of thermal management solutions can be checked on a reasonable source of power, in a power biking atmosphere.

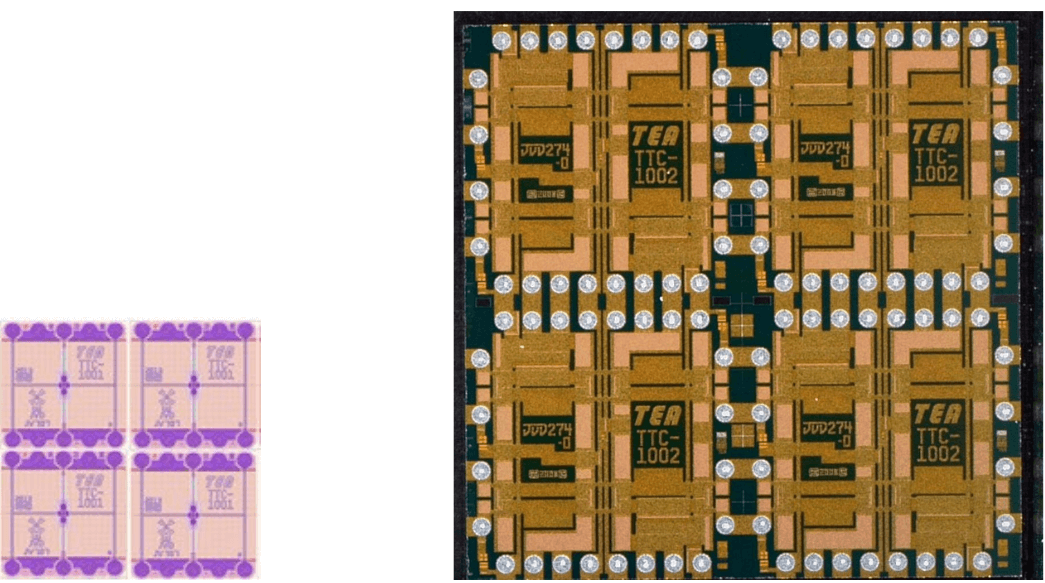

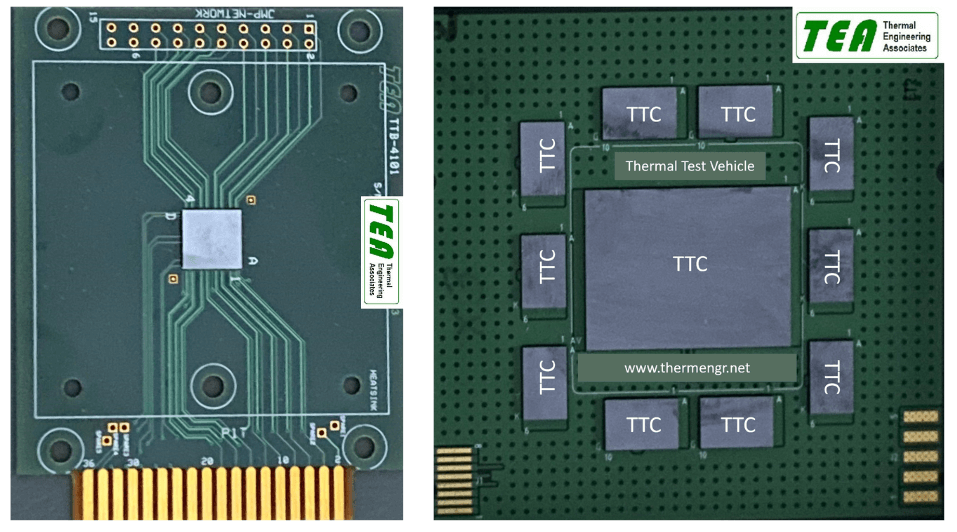

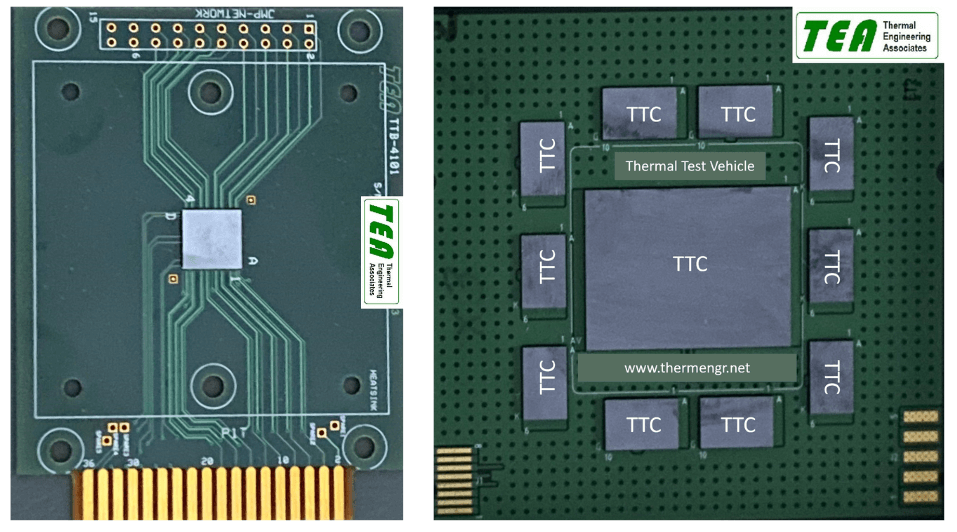

In feedback, thermal examination chips (TTC) and thermal examination automobiles (TTV) have actually been established to resolve this difficulty (Number 1).

TTCs can properly replicate the non-uniform power circulation (“hot spots”) of a genuine semiconductor chip, with ingrained on-chip sensing units for real-time and precise temperature level dimension of the chip, giving the capacity for configurable power circulation and sitting temperature level dimension on the chip– to the range of a System Cell (1mm x 1mm)

Vital technological factors to consider consist of harmony and matching throughout the wafer, and continuous power dissipation throughout the thermal dimension, for the warmth resource. Correspondence to the JEDEC JESD51-4 requirement is likewise a really crucial need. An additional crucial factor to consider is the Temperature level Sensing Diodes (TSD), much less than 35µm in measurement, for real-time exact dimension of the temperature level of the die at several places concurrently.

Versatile, steady, and precise TTCs can be a dependable thermal double of numerous semiconductor chips, from chiplets as little as 1mm x 1mm to big chips and interposers (as much as 50mm x 50mm, or bigger if required). The TTC, with its accuracy and precision of the incorporated heating units and sensing units in each Device Cell, can properly replicate the thermal actions of a genuine semiconductor chip and consequently supplies a fantastic device for simultaneous development of thermal management solutions while a brand-new chip is under development (which usually takes numerous years).

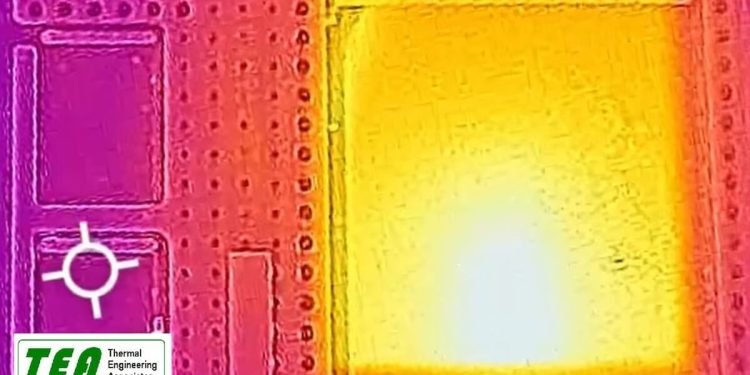

A TTC can have several home heating areas and temperature level sensing units, each separately managed and kept an eye on, to mimic the thermal actions of the numerous practical blocks in a genuine chip. Number 2 reveals an instance of the TTC with non-uniform home heating. At the exact same time, the TTC is very easy to run and usage, as its single feature is to replicate the power circulation and procedure the temperature level throughout the contribute real-time, without the various other features of a genuine chip that are not required for this function.

With the TTCs (made for cable bonding or flip chip add-on), TTVs (Number 3) can be established in numerous packaging styles, such as BGA, LGA, COB, and so on, along with multi-chips per bundle to replicate system-in-package (SiP) that is usually utilized for heterogeneous assimilation. TTCs can likewise be set up for advanced packaging, such as multi-die piling, glass interposer, and so on

Utilizing the TTCs and TTVs to carry out thermal dimensions and screening in genuine real-life atmosphere (i.e., utilizing real-life TIMs and cooling down solutions), the spatial and temporal temperature level circulation over the chips can be identified, and the thermal efficiency of the whole bundle can be analyzed, with high integrity and self-confidence.

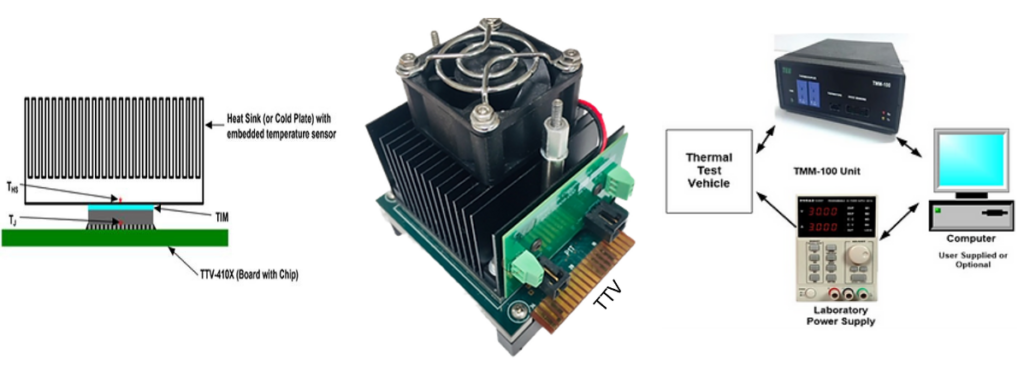

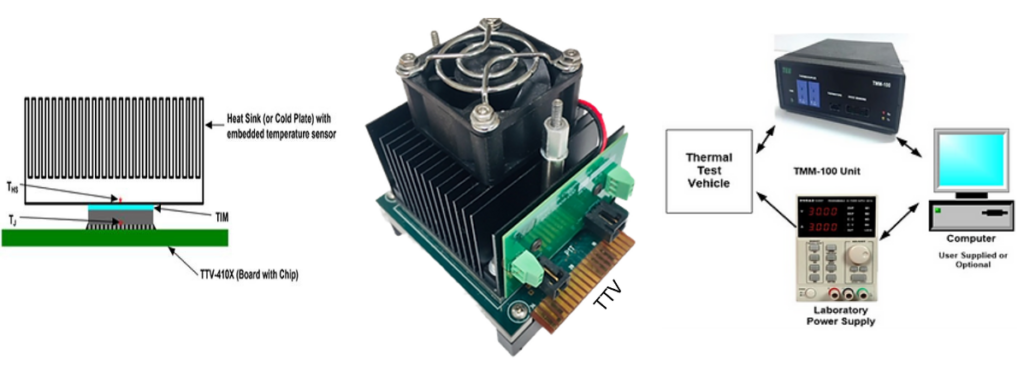

For instance, a TTV can be utilized for TIM thermal characterization under application-oriented dimension problems (Number 4).

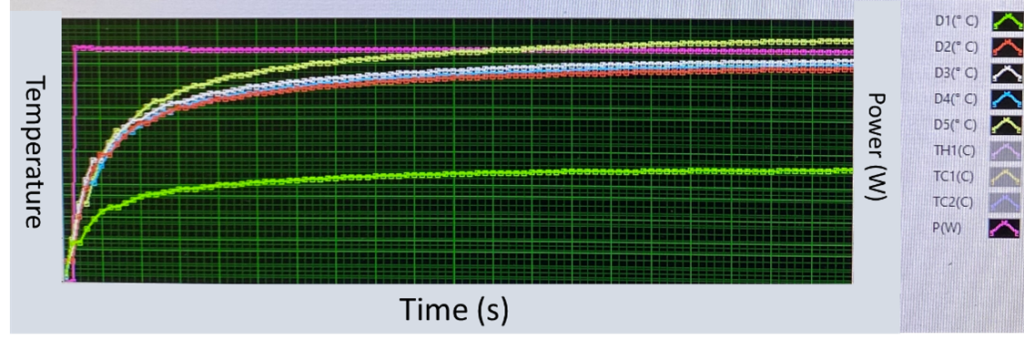

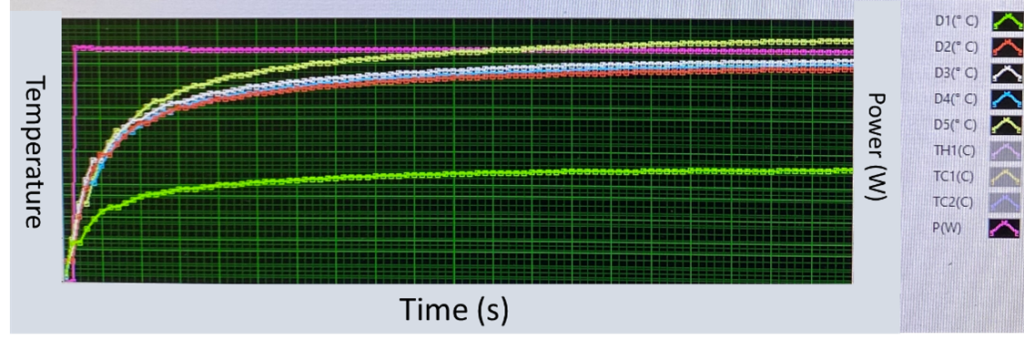

Number 5 reveals an instance of the temperature level advancement at numerous places throughout a chip when the TTC is powered at a certain power degree. Based upon the dimension, the thermal insusceptibility and resistance of the bundle utilizing numerous thermal management solutions can be computed. The accessibility of these devices develops a de facto requirement that makes it possible for both TIM suppliers and TIM individuals to contrast dimension outcomes under the exact same problems.

Therefore, with the capacity for configurable power circulation and synchronised temperature level dimension throughout the chip, TTCs and TTVs can be really helpful for thermal characterization (constant state and short-term) and assessment, consisting of power and/ or temperature level mapping, for semiconductor plans and tools, which can include numerous thermal management solutions. They can likewise be really helpful for verifying thermal simulation and modeling.

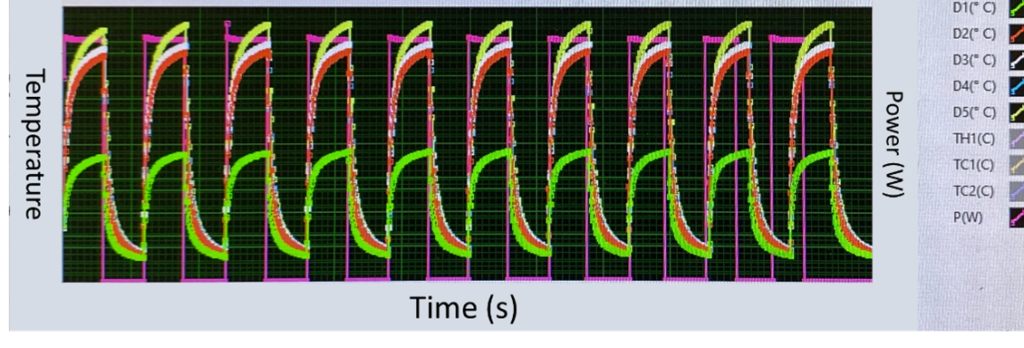

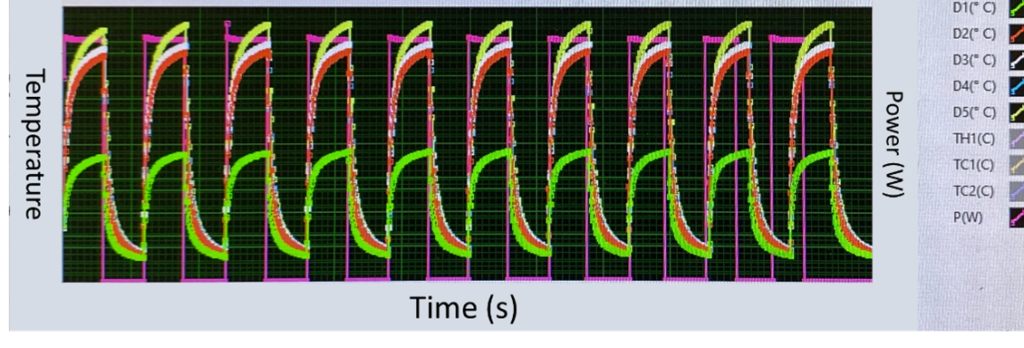

Moreover, power biking can be performed in a configured readying to assess the dependability efficiency of numerous thermal management solutions. Number 6 is an instance of the temperature level advancement at numerous places in a chip throughout power biking. With this setup, pump-out can be researched in the power biking setup. TIMs with problems can likewise be researched for their influence on thermal efficiency for real-life applications.

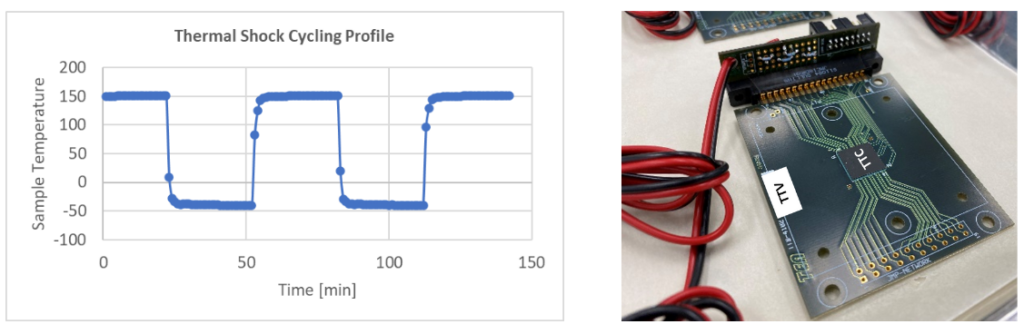

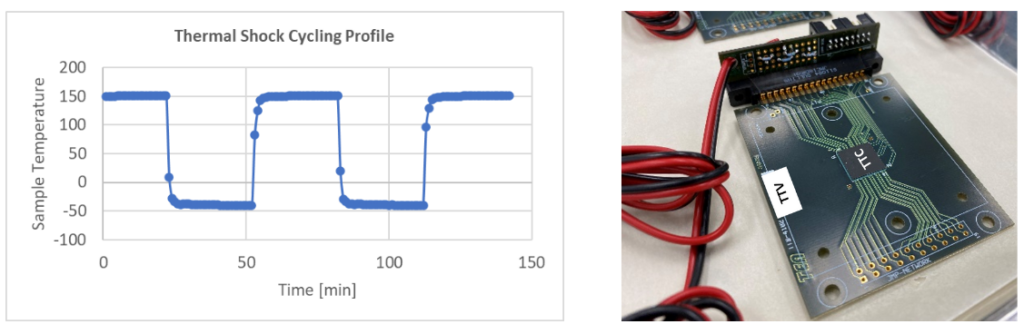

Certainly, the TTVs themselves need to be reputable. Current screening by a big U.S.-based firm has actually shown the dependability of the TTVs with 1000 cycles of -40 C/150C thermal shock screening (Number 7).

With the capacity to utilize TTVs as a de facto conventional device, thermal management solutions can be maximized in quick models, in a real-life atmosphere. Such characterization can be done utilizing various dimension TTCs and at various power degrees to evaluate the efficiency for various applications. The exact same TTV can be utilized often times to make the screening results similar and goal.

A lot more significantly, with a TTV, programmers of thermal management solutions– in sector and academic community– can create the future generation of products and cooling down solutions, by utilizing the TTV at a power degree that has actually not yet been recognized in genuine chips, therefore allowing development for the future.

On The Whole, TTCs and TTVs are terrific devices to allow the rapid development and optimization of thermal management solutions, eventually making certain the thermal honesty of semiconductor tools, dependably and cost-effectively.

For additional information, please call Dr. Dongkai Shangguan dongkai@thermengr.com.